New Paradigm Industries, Innovative Solutions Inc.

New Paradigm Industries, Innovative Solutions Inc. 2015

Incorporated Under CBCA, RSC 1985, c C-44

Follow us on

LinkedIn

Facebook

Complete Refurbishment of Glovebox

This project involved the complete refurbishment of a heavily “used” and

out of service glovebox, as to bring it back to full functionality.

Some of the features of this project include;

- fabrication of missing 2” recirculation lines, with KF connection fittings

- fabrication & installation of adapter plate, and replacement of -80 freezer

- replacement of all seals, gloves, gaskets, and leak testing of unit

- rebuilding of catalyzer including replacement of copper catalyst and

molecular sieves, as well as initial commissioning of glovebox

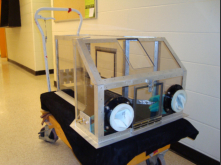

Microscope Enclosure

This microscope enclosure was custom designed and fabricated for nano

research applications to provide a clean environment for sample

observation and certain experimental applications.

Some of the design features include;

- 1/4” lexan and aluminum frame construction, 2 x access doors. 8 x pass

through ports, glove portals for sample and microscope interface

- provision of inert gas inlet ports, and sealed to maintain positive pressure

- includes mounting holes to be affixed to bread board or optical table

Vented Enclosure for CVD System and Gas Handling System

This apparatus was custom designed and fabricated to house the CVD

System, as well as to provide a secondary level of protection during it’s

operation as well as for the storage of associated compressed gases.

Some of the design features include;

- 1/4” lexan panels with aluminum framing, 2 x bifold doors providing

ample access to equipment, built around heavy-duty shelving system

- vented cylinder storage area, and deep-T purge for ammonia gas system

- independent vented pump cabinet

Ultra High Purity Gas Distribution System

This project involved the design, fitting, and installation of an ultra high

purity gas distribution system to support up 4 to Mass Spectrometers

Some of the features of this project included;

- specification and use of components matching the requirements of the

application, including electro-polished tubing and BQ standard Swagelok

- Integration of distribution lines with previously supplied custom bench

work, as to provide connections where necessary while keeping area clean

- fabrication, and installation of custom tubing supports and valve mounts